This 6-axis robotic gas-shielded welding system is specifically designed for carbon steel plate welding. It features a 2.0-meter rotating arm with a built-in welding torch and a 350A low-spatter power source, achieving high repeat positioning accuracy of ±0.08mm. With a working range of ±165° and a welding speed of 0.3-1.0m/min, the system covers a current range of 30-350A, making it suitable for welding Q195, Q235, and other carbon steel plates with thicknesses of 1.2-5.0mm. It ensures low spatter, minimal slag, and arc re-ignition capability, requiring workpiece tolerances within ≤0.5mm.

The matching 2000×2000mm rotary platform is available in two height configurations (700mm and 400mm) and adopts a servo motor drive with slewing bearing support, offering a load capacity of 300kg. The platform enables 0°-180° forward/reverse rotation positioning controlled by the robot, forming a complete workstation for high-stability, low-failure welding production.

Welding production line

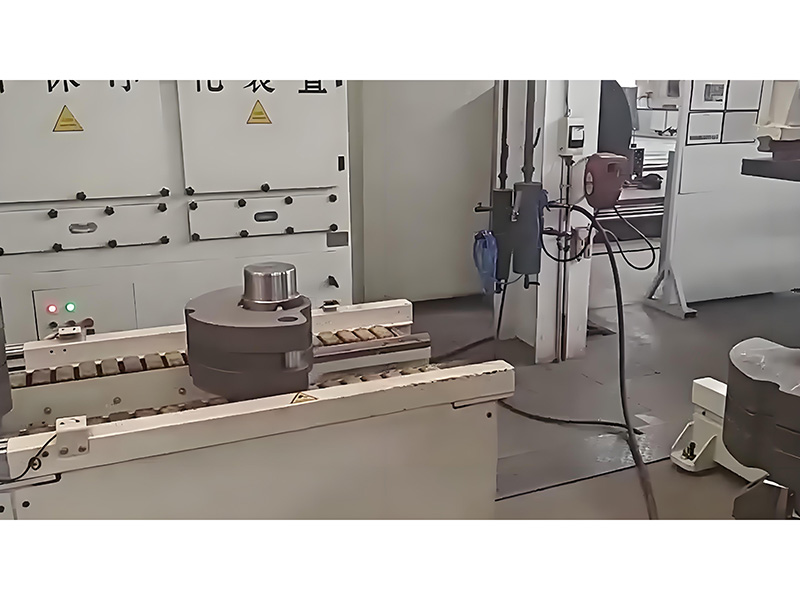

After manual assembly, tacking, and welding (internal welds) on the fixture, the workpiece is automatically transported to the conveyor line.

The workpiece is then automatically transferred to the welding positioner, which clamps it automatically and rotates to the desired angle (360° adjustable). The welding robot performs automatic welding.

After welding, the positioner moves to the manual grinding area, where workers grind the workpiece while the positioner rotates and tilts for full accessibility.

Usage environment

Three-phase AC power supply: 380V (±10%), 50Hz

Single-phase AC power supply: 220V (±10%), 50Hz

Ambient temperature: -20°C to 45°C

Humidity: 50% to 90%

Compressed air: 0.5MPa to 0.7MPa

Welding conditions

Welding method: Rich argon gas-shielded arc welding (80% Ar + 20% CO₂)

Welding position: Flat welding (fillet welding in the horizontal position), horizontal fillet welding

Welding wire: 1.2mm solid wire

Wire extension length: 22mm

Welding oscillation width: 0–30mm

Comments on “Easy-maintainable 6-axis robotic gas-shielded welding system v”